Still working to recover. Please don't edit quite yet.

elevator

An elevator is a transportation device used to move goods or people vertically. In the United Kingdom, elevators are known more commonly as lifts, although the word elevator is familiar from American movies and television shows. Other languages may have loanwords based on either elevator (e.g. Japanese) or lift (e.g. Cantonese). Because of wheelchair access laws, elevators are often a requirement in new buildings with multiple floors.

History[edit]

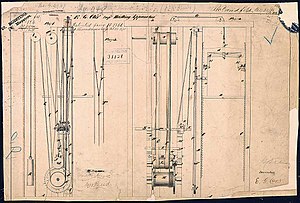

Elevators began as simple rope or chain hoists. An elevator is essentially a platform that is either pulled or pushed up by a mechanical means. A modern day elevator consists of a cab (also called a "cage" or "car") mounted on a platform within an enclosed space called a shaft or more correctly a "hoistway". In the past elevator drive mechanisms were powered by steam and water hydraulic pistons.

In a "traction" elevator, cars are pulled up by means of rolling steel ropes over a deeply grooved pulley, commonly called a sheave in the industry. The weight of the car is balanced with a counterweight. The friction between the ropes and the pulley furnishes the traction which gives this type of elevator its name.

Hydraulic elevators use the principal of hydraulics to pressurize an above ground or in-ground piston to raise and lower the car. Roped Hydraulics use a combination of both ropes and hydraulic power to raise and lower cars. Recent innovations include permanent earth magnet motors, machine room-less rail mounted gearless machines, and microprocessor controls.

Which technology is used in new installations depends on a variety of factors. Hydraulic elevators are cheaper, but installing cylinders greater than a certain length becomes impractical for very high lift hoistways. For buildings of much over seven stories, traction elevators must be employed instead. Hydraulic elevators are usually slower than traction elevators.

In 1823, an "ascending room" made its debut in London[1].

In 1853, Elisha Otis introduced the safety elevator, which prevented the fall of the cab if the cable broke. The design of the OTIS safety is somewhat similar to one type still used today. It consists of knurled roller(s) that lock the elevator to its guides should the elevator descend at an excessive speed, which is monitored by a governor device.

On March 23, 1857 the first Otis elevator was installed at 488 Broadway in New York City. The first elevator shaft preceded the first elevator by four years. Construction for Peter Cooper's Cooper Union building in New York began in 1853. An elevator shaft was included in the design for Cooper Union, because Cooper was utterly confident a safe passenger elevator would soon be invented; the shaft however was circular because Cooper felt it was the most efficient design. Later Otis designed a special elevator for the school. Today the Otis Elevator Company, now a subsidiary of United Technologies Corporation, is the world's largest manufacturer of vertical transport systems, followed by Schindler, Thyssen-Krupp and Kone, in order.

The first electric elevator was built by Werner von Siemens in 1880. The safety and speed of electric elevators were significantly enhanced by Frank Sprague.

The development of elevators was led by the need for movement of large amounts of raw materials including coal and lumber from hillsides. The technology developed by these industries and the introduction of steel beam construction worked together to provide the need for the passenger and freight elevators we use today.

Modern elevator construction[edit]

Today, elevators are built under strict supervision of the Building Codes. Model Codes which are the standard in most US and Canadian jurisdictions require compliance with the American Society of Mechanical Engineers' standards for the installation, maintenance, and inspection of elevators. In addition other related standards are likely required to be complied with as specified by Local Authorities Having Jurisdiction.

Elevators are generally sold in prepackaged components which are inherently non-proprietary. All of the four major manufacturers sell proprietary microprocessor controls. Each manufacturer provides similar product designs, and the overriding issue for purchase is usually price and availability. In the case of renovations, the use of non-proprietary controls has become a large part of that business because it allows the owner to offer the maintenance contract to multiple bidders rather than accept a single manufacturer for the life of the elevator which can be more than 30 years. In some large campus type properties, the use of non-proprietary equipment in new construction has replaced the standard prepackaged product. Non-proprietary systems generally have a higher up front cost, but may be offset by allowing the owner to control the long term costs over the life of the elevator.

In some locations, the shaft and parts of the cab are made of transparent material for specialized "Scenic elevators." This allows riders to see outside the cab as they travel on the elevator. Some locations take advantage of this transparent material by placing the elevators along the walls of their building. This allows riders to see the outdoor environment as the cab runs along the side of the buildings.

Today, all new elevators are computer-controlled and microprocessor based. This allows the elevator system to place cabs where they are most needed in the interest of smooth running, with behavior based on analysis of building use called "Traffic Studies." Traffic Studies are done by professional elevator consultants who use specialized tools to determine the optimum size, speed and number of elevators for a building based on its peak use periods. Computer control also permits greater control of access to various floors of a building after hours and on weekends. Methods of access control include card readers, keys, and access codes entered into the control panel of the elevator.

Elevators are usually installed in a building during construction. Renovations may consist of replacements for hoistway (floor landing) doors, car doors, interior cab finishes, controls, hoist machines, hydraulic pistons and hall fixtures. At times renovations may also include replacement of the entire cab itself. In many instances the upgrading of components may require additional code compliance, these issues should be reviewed with an elevator consultant prior to the purchasing of new materials.